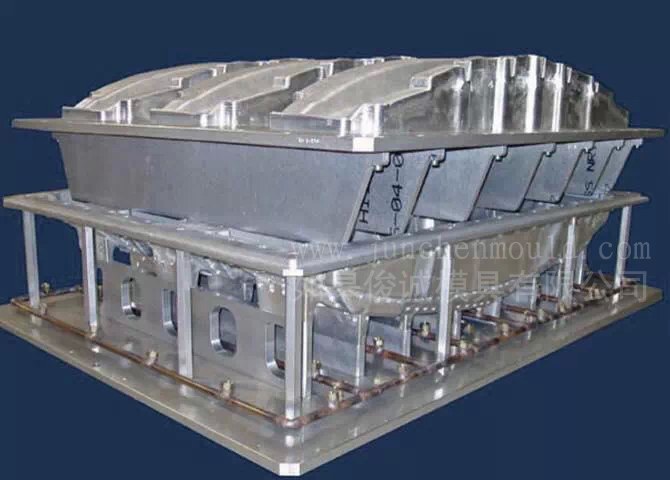

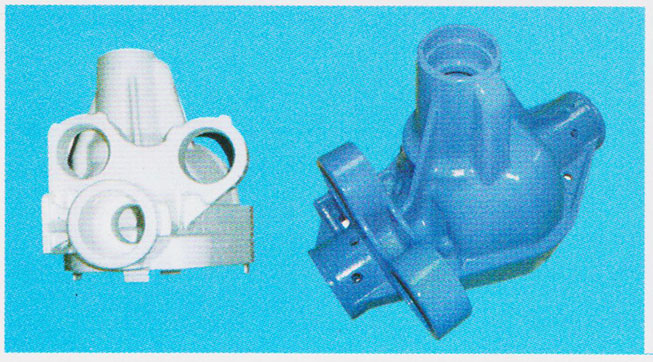

- >>·EPS Mould

- >>·EPP Mould

- >>·EPE Mould

- >>·Fixture design

- >>·Decoration Mould

Rugao Juncheng Mould Co., Ltd.

Contact:Mr.xue

Telephone:086-0513-87602399

Phone:086-15262848587

Fax:086-0513-87602466

QQ:549694928

E-mail :junchenmould@163.com

Website:www.junchenmould.com

Address:China jiangsu rugao towns such as Song Guqiao village 19 15 groups

当前位置:首页 > News News

Daily maintenance and maintenance of automobile mould

One, the maintenance of mold

The upper and lower surfaces of the mold shall be cleaned, and the die mounting face and the press working table are not pressed and the parallel degree of the die is installed in the production.. The mold after installed the mold is opened, the various parts of mold clear clean, especially guiding mechanism, for surface mold, the surface cleaning wipe clean, in order to improve the workpiece quality. Lubricate the sliding parts of the mould, grease the grease.. Check the mold parts, especially the safety parts.. Such as: safety side pins, safety screws, side protecting plate, punching waste way etc.

Two, the maintenance of production

In the production of regular dies on the corresponding parts of oil. Such as: binder, fillet drawing die; edge trimming die; flanging cutter block part etc.. The cleaning of the waste material in the hole of the trimming punching die is cleaned regularly..

Maintenance after production

After the production to mold a comprehensive inspection.

The mold carries on the comprehensive cleaning, the guarantee mold cleanliness.

Clean the waste in the mold, and ensure the waste is free from the waste..

Feedback the use of the mold and the use of the situation truthfully to the mold summons.

Mold two maintenance

Mold two maintenance refers to the mold according to the technical state and complexity of the mold carried out the regular system maintenance. This maintenance is done by the mold repair personnel and records according to the maintenance. The following requirements and methods for the description of the second guaranteed for different parts.

Drawing die convex and concave die, drawing die of convex and concave mold mainly is galling and surface indentation, maintenance mainly to die fillet galling parts of polishing. If the pressure pit to the mold repair welding, and then the repair.

The guide parts (guide pillar, a guide sleeve and a guide plate): die will appear the phenomenon of stretch marks in the work. The main reasons are the lubrication oil dirty and the guide gap, etc.. The guide parts take to eliminate stretch marks with push along the way after the polishing stone.

Trimming knife: knife mold in the process of using easily chipping and edge collapse phenomenon. At this time to damage to the die of blade repair welding repair spring elastic parts: in the use of the process, the spring is one of the mold the most easily damaged parts, usually appear the phenomena of fracture and deformation. The approach taken is replaced, but the replacement process, be sure to pay attention to the specifications and models of spring, spring and specifications by color, outer diameter and length of the three identified, only in this three have the same situation can be changed.

Punch, punch sets: mold punch, punch sets most of the standard parts and mould in use in the process of punch is easy to appear broken, bend and eating the bad phenomenon. Punching sets are generally eating bad. Punch and punch sets damage generally use the same specification for replacement parts. The main parameters of the working part of the punch size, size, length and installation.

Fastening parts: check the loose parts loose, damage phenomenon. The way is to find the same specifications for the replacement of parts. Pressing and unloading parts: pressing parts such as pressure plate, rubber, unloading parts such as stripper, pneumatic lifting device etc..

Maintenance of the parts of the assembly relationship and damage, repair damage. Pneumatic roof material check the phenomenon of leakage, and the concrete situation to take measures. Such as tracheal damage replacement, etc.

In the previous:Automobile mold enterprise to the tall on the route The next article:Auto mold is the most important in the mould Market in China.

- Related products

- Related news

- 2015-06-04 Auto mold is the most important in the mould Market in China.

- 2015-06-04 Daily maintenance and maintenance of automobile mould

- 2015-06-04 China's auto mold industry to lead the industry of independent manufac...

- 2015-06-04 Automobile mold enterprise to the tall on the route

- 2015-04-18 家电业施展“抄后路”战术

- 2015-04-18 2015广州3D打印展会之高峰论坛会特别报道(一)

- 2015-04-18 使用3D打印发动机的世界首枚电池动力火箭Electron

- 2015-04-18 巧克力3D打印机亮相广交会

- 2015-04-18 著名桌面3D打印机公司MakerBot突然裁员20%