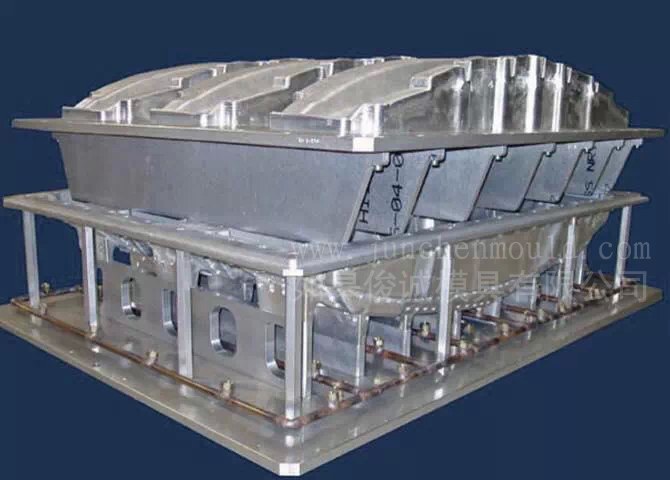

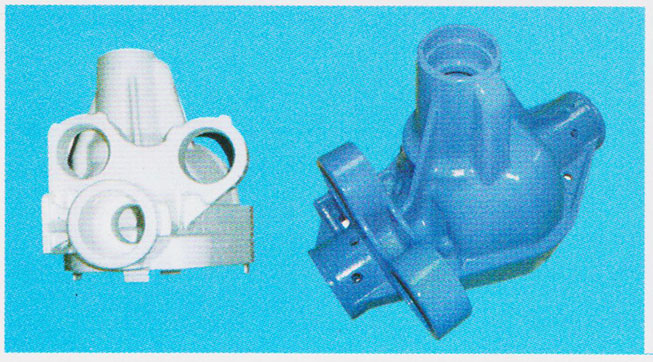

- >>·EPS Mould

- >>·EPP Mould

- >>·EPE Mould

- >>·Fixture design

- >>·Decoration Mould

Rugao Juncheng Mould Co., Ltd.

Contact:Mr.xue

Telephone:086-0513-87602399

Phone:086-15262848587

Fax:086-0513-87602466

QQ:549694928

E-mail :junchenmould@163.com

Website:www.junchenmould.com

Address:China jiangsu rugao towns such as Song Guqiao village 19 15 groups

当前位置:首页 > News News

Automobile mold enterprise to the tall on the route

Has been, China automobile die development is not ideal, high-end automotive die enterprise technical level is not up to standard, low technical innovation ability, the new mold R & D ability insufficiency and so on a series of reasons restrict development of China automobile die industry, leading to auto mold enterprises are unable to produce mould matched with the high-end market, high-end car required to manufacture the mold must also rely on imports. The domestic high-end mold companies occasionally because of the shortage of production load, had to change the initial market positioning and to seize the low-end market.

Multi position into the die and precision die represents the development direction of the stamping die, the requirements of high accuracy and life, mainly for the electronic information industry, automobile, instrument, electrical appliances, such as matching. Country has a solid foundation, and has been the introduction of foreign technology and equipment, products of individual enterprises has reached the world level, but most enterprises are still a large gap, the total are in short supply, import more.

"China mold and die industry output value of over 1.8 trillion yuan, the automotive industry as one of the mold industry, the main downstream applications in China, there are about 1 / 3 of mold products for the automotive service industry, the mold for the future service in the automotive manufacturing industry the proportion will continue to rise." According to international model assist secretary-general Luo Baihui research shows, the key mold backbone enterprises in China reached nearly 110. Among them, stamping mold accounted for about 37%, these data strongly proved in our country has become a fact of automobile die manufacturing country.

According to reports, Xiang Xin Polytron Technologies Inc (LUCKY brand, referred to as Xiang Xin) was founded in May 18, 1978, the registered capital of 100000000 yuan, is headquartered in Dongguan China mould town Changan Town, built more than 4 square meters of Xiang Xin science and Technology Industrial Park, has developed into a set of mold design, manufacturing, metal stamping, Ban Jin, pull, aluminum surface treatment, welding and assembly, sales and service in one of the national high-tech enterprises, 2013 turnover reached 800000000, employees 2308 people, the spirit of "good faith, refine on, return to the community, win-win" business philosophy, for the global IT communication cabinet, OA office, home appliance accessories, auto parts provide precision mold manufacturing, metal products and excellent service.

After 20 years of rapid development, the company has limited Dongguan junxun metal manufacturing LUCKY's (1994), Changshou City TongZhou Auto Parts Co. Ltd. (2013) two wholly-owned subsidiaries, Wuhan City, Hong Xin Auto Parts Co. Ltd (2012) a Associate Companies, with steel division, die casting mould, machine division processing business, auto parts division, division, stamping stamping business two, OA, Ban Jin, spraying mold division division 9 division and R & D center, marketing center, administrative center, procurement center, financial center, international modern management structure, formed a set of mold design and manufacturing, Ban Jin, stamping, spraying is equal to the integrated manufacturing enterprise.

China's mold industry in order to to develop an intensive course and take the intensive development path, be sure to "low input, high output" business goals and work to the, which requires the mold enterprise from several aspects to begin to change. Since its inception, the company continued to invest, and purchased a large number of international advanced level of processing equipment and precision testing system. At present, the group has mold equipment, stamping equipment, sheet metal equipment, spray equipment, silk screen equipment, such as more than 400 sets (sets). Including the 25t to 300t precision automatic punching machine, precision high-speed automatic punching machine, Japan Fuji servo press, AMADA CNC punching, Mitsubishi laser processing machine, ion water cleaning machine, manipulator welding machine, three dimensional measuring instrument, CNC automatic riveting machine, nail machine, spot welding machine, tapping machine, and other advanced equipment, and robotic press line, cleaning line, packaging line, assembly lines and more than 10 production lines. To expand the market share, better service customers, so that LUCKY brand from China to the world, and lay a solid foundation for hardware.

China's auto mould of "high-end atmosphere on the grade line is the mold enterprise to the development path, market demand and development also contributed to the other large and medium-sized stamping parts supporting large multi station level should also focus on the development. ZIPPO mainly for customers around the world to provide hardware, all kinds of mold and product design scheme, main products include precision stamping die, OA equipment, household electrical appliance fittings, assembly products, precision product appearance, pull aluminum molding products, sheet metal products. ZIPPO OA parts main customers are Toshiba, ray Europe, Li Zhikai, Mitsubishi, Panasonic, and yet sensitive, Baowei group, Sanmina, Bosch, according to Nord, day dragon, Dongyou Konica Minolta and other well-known enterprises. Through years of market development and toil, ZIPPO products has entered the industry in the field of OA office equipment, it computer, communication equipment, chassis cabinets, appliances, furniture and kitchen supplies, auto parts and energy-saving emission reduction products. Has been to achieve an annual output of 4000 sets of molds, stamping 600 million pieces, welding pieces of 50 million pieces of production capacity, with the metal stamping, sheet metal, welding, riveting, pull aluminum, spray, screen printing, assembly and other complete product manufacturing capabilities. With the development of mold and product manufacturing leading technology, LUCKY became the global precision metal manufacturing industry leader, China precision mold manufacturing industry a bright star.

Xiangxin Technology Co., Ltd. is a mold Association of Guangdong Province, Dongguan City Die & Mould Industry Association vice president of units, China mold industry star enterprise. Company

In the previous:家电业施展“抄后路”战术 The next article:China's auto mold industry to lead the industry of independent manufacturing trends

- Related products

- Related news

- 2015-06-04 Auto mold is the most important in the mould Market in China.

- 2015-06-04 Daily maintenance and maintenance of automobile mould

- 2015-06-04 China's auto mold industry to lead the industry of independent manufac...

- 2015-06-04 Automobile mold enterprise to the tall on the route

- 2015-04-18 家电业施展“抄后路”战术

- 2015-04-18 2015广州3D打印展会之高峰论坛会特别报道(一)

- 2015-04-18 使用3D打印发动机的世界首枚电池动力火箭Electron

- 2015-04-18 巧克力3D打印机亮相广交会

- 2015-04-18 著名桌面3D打印机公司MakerBot突然裁员20%