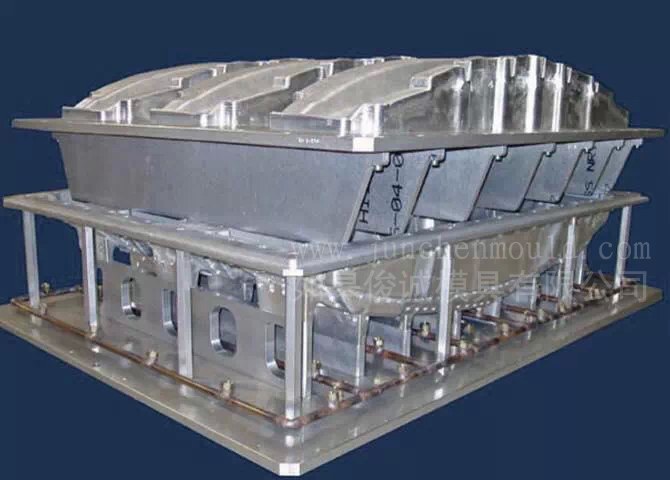

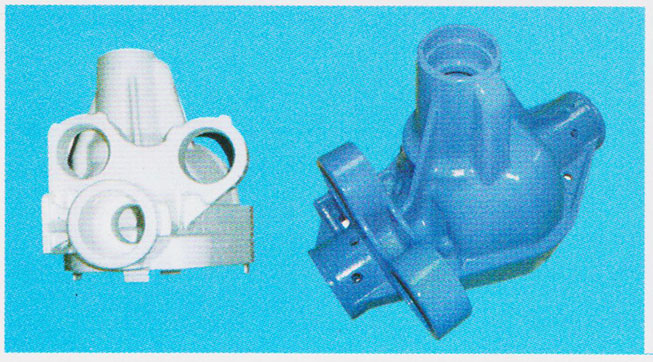

- >>·EPS Mould

- >>·EPP Mould

- >>·EPE Mould

- >>·Fixture design

- >>·Decoration Mould

Rugao Juncheng Mould Co., Ltd.

Contact:Mr.xue

Telephone:086-0513-87602399

Phone:086-15262848587

Fax:086-0513-87602466

QQ:549694928

E-mail :junchenmould@163.com

Website:www.junchenmould.com

Address:China jiangsu rugao towns such as Song Guqiao village 19 15 groups

当前位置:首页 > News News

China's auto mold industry to lead the industry of independent manufacturing trends

Gold Mould Network Industry Research Center of automobile enterprises is the first assembly oriented enterprises, real technology is actually more in the hands of the parts and components enterprises, parts enterprises products batch production is realized by molding. In recent years, the auto industry is changing speed, the demand of market diversification is amazing, and the potential market of automobile mold is huge..

International Mould and hardware plastic industry suppliers association secretary long Luo Baihui said in automotive transmission system, steering system, body parts, engine products high-end parts we are still dependent on imports, mold equipment is an important part of vehicle equipment, each kind of new models of cars need thousands of deputy dies, on the value of the yuan, and China's large-scale precision mold manufacturing capacity insufficient. Like the mid-range Passat body die more than 2.5 billion yuan, large plastic mold about 35 million to 40 million, China has been able to C production car mid-range car cover mold and die, dashboard bumper plastic mould we can very good finish, but of upscale cars in China cover mold almost all imported products.

From the heart of the automobile generator of cylinder block casting to stamping parts in automobile body in white, from speeding up the development process of China's energy-saving environmentally friendly vehicles such as to the generation of metal plastic, injection mold realize automobile engine plastic intake manifold foreign accounted for 80%, this process makes the combustion more complete, the quality is light, to new material super steel hot forming die; lightweight of automobile new material forming die and multi position into the mold is to promote the development of independent brands of cars the security, in order to reduce the weight, aluminum alloy and other light metals in automotive applications will be increased, and to adapt to the mold will also develop.

Luo Baihui pointed out that with the development of the integration of the mold clip, the integration of the mold clip is bound to be developed. All need to mold driven by manufacturing of autonomy in the core components of the automotive industry, in the future market of the mold, plastic mold in the mold total quantity the proportion will gradually improve, its development speed will be higher than other molds. In the automobile OEM mold enterprise status is already a kind of core competitiveness status; for the automobile OEM service at the mold enterprise is a strategic alliance closely related. It can be predicted that with the rapid development of China's auto industry and the higher level of development, it will drive the continuous and stable development of the automobile mould market..

Shanghai Saikeli automobile mould Co., Ltd will also showcase body covering parts and large stamping parts mold, including four doors, engine cover, trunk lid, side wall, fender, roof and floor parts of die, progressive die stamping mold, multi position stamping die, laser tailor welded plate blanking die etc.. Auto parts large progressive die also showed considerable strength, of which there are representative of the car trunk structure Tianjin Jinzhao electromechanical Development Co., Ltd. is the production of large precision progressive die, 14T of weight and length 4m, module precision of 5um, die life 300 million times, mold design and manufacturing level reached the technical level of similar foreign products.

FAW die manufacturing company for Land Rover Rover production of high-grade car aluminum alloy stamping die, a total of 23 parts, a hundred sets of mold has factory in Liverpool, Birmingham and put into use; it will be exhibiting at the AudiA6L high-grade car front fender parts to the free state combination lattice of dimension tolerance and good surface accuracy, indicating that the domestic mold manufacturing enterprises have been able to design and manufacture all types of body panel die. Fuzhen Anhui Jianghuai Vehicle Equipment Co., Ltd. and Anhui Rui gue motor dies company will bring single row cover outer plate, a front wall and the roof, left rear door inner and outer plate, left surround, instrument panel on the outer plate and appearance quality requirements of high, complex shape, deep drawing, the large size of the car mold and display technology.

Xiang Xin Polytron Technologies Inc (LUCKY brand, referred to as Xiang Xin) was founded in May 18, 1978, the registered capital of 100000000 yuan, is headquartered in the town of Dongguan Changan China mold town, built more than 4 square meters of Xiang Xin science and Technology Industrial Park, has developed into a set of mold design and manufacturing, five Jin Chongya, Ban Jin, pull aluminum, surface treatment, welding, assembly and sales and services in one of the national high-tech enterprises, 2013 turnover reached 800000000, employees 2308 people, the spirit of "excellence, integrity compliance, win-win and return to society" business philosophy, for the global IT communication cabinet, OA office, home appliance accessories, auto parts provide the precision mold manufacturing, metal products and excellent service. Since 2007 Xiangxin continuous access to the "Changan Town tax big companies," outstanding private enterprise ", won the" Dongguan City of private science and technology enterprise "," Guangdong Province private science and technology enterprise "," Guangdong Province, the contract Shou Credit Enterprises "," national high tech enterprise "honorary title. In 2009, Xiang Xin launched the "auto parts stamping production line technological transformation project, this project in 2013 September by the Dongguan City Council by letter of acceptance; in 2011, Xiang Xin launched the" new energy vehicles, metal mold parts production line technological transformation project "; in 2012, Xiang Xin launched the" project "large automotive parts of die stamping production in 2013 March; Xiang Xin, in cooperation with the South China University of Technology developed automotive air conditioning special collector tube whole stamping technology research and application projects; in 2013 March, Xiang Xin," a new type of flanging and stretching process of mold development "by the Dongguan Municipal Science and Technology Bureau identified as" with the leading domestic level "; in 2013 August, Xiang Xin and Guangdong University of Technology jointly developed a key leading Guangdong

In the previous:Automobile mold enterprise to the tall on the route The next article:Auto mold is the most important in the mould Market in China.

- Related products

- Related news

- 2015-06-04 Auto mold is the most important in the mould Market in China.

- 2015-06-04 Daily maintenance and maintenance of automobile mould

- 2015-06-04 China's auto mold industry to lead the industry of independent manufac...

- 2015-06-04 Automobile mold enterprise to the tall on the route

- 2015-04-18 家电业施展“抄后路”战术

- 2015-04-18 2015广州3D打印展会之高峰论坛会特别报道(一)

- 2015-04-18 使用3D打印发动机的世界首枚电池动力火箭Electron

- 2015-04-18 巧克力3D打印机亮相广交会

- 2015-04-18 著名桌面3D打印机公司MakerBot突然裁员20%